依據歐盟施行的個人資料保護法,我們致力於保護您的個人資料並提供您對個人資料的掌握。

按一下「全部接受」,代表您允許我們置放 Cookie 來提升您在本網站上的使用體驗、協助我們分析網站效能和使用狀況,以及讓我們投放相關聯的行銷內容。您可以在下方管理 Cookie 設定。 按一下「確認」即代表您同意採用目前的設定。

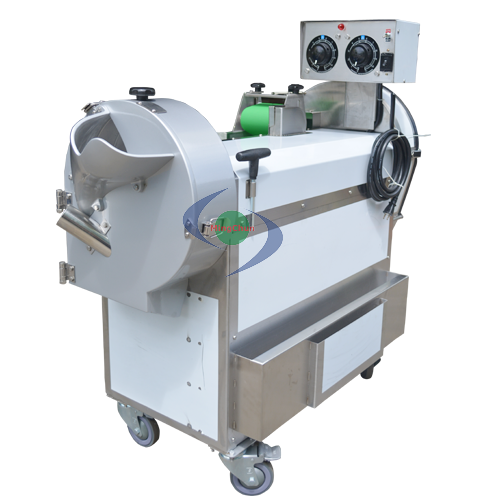

真空按摩機 Automatic Massager Marinating Machine MG-208/210/211/212/215/217

真空嫩化機

食品真空按摩機(又稱真空滾揉機)是一種專為肉品、水產和調理食品設計的加工設備,透過在真空狀態下進行物理滾動與撞擊,達到快速醃製、嫩化和提升品質的效果。

食品真空按摩機針對各類肉品(豬、牛、羊、雞等)、水產品、調理食品、農產品、素食品等。嫩化、醃製功能進行加工。

Automatic Massager Marinating Machine MG-208/210/211/212/215/217

Vacuum Meat Tumbler Massager

Food vacuum massage machine (also known as vacuum tumbling machine) is a type of processing equipment designed specifically for meat, seafood, and processed food, achieving rapid marination, tenderization, and quality enhancement through physical rolling and impact in a vacuum state.

- 廠商名稱威綸機械有限公司

►縮短醃製時間、提升效率

在真空環境中,肉品與醃料更緊密接觸,能大幅縮短醃漬時間,提升生產效率。

►改善肉質與保水性

透過滾筒內的翻滾與撞擊,使肉品更均勻地吸收醃料,增加保水性,提升產品的彈性與口感。

►穩定品質、提升一致性

自動控制系統可設定按摩、休息、總時間與轉速,確保每批產品的一致性與穩定性。

►模擬人工按摩動作

在真空狀態下,肉品在滾筒內上下翻動,模擬捏、柔、槌、打、摔等動作,使肉品更入味且質地柔嫩。

機械特性與操作優勢

全機不銹鋼設計:符合食品衛生標準,易於清洗與維護。

無段變速控制:可根據不同產品需求調整轉速,靈活應對各種加工需求。

多組記憶控制面板:可儲存多組加工參數,方便快速切換產品線。

正反轉功能與反轉下料:提高出料效率,減少人工干預。

緊急停止與暫停功能:操作更安全,並可在運作中檢視加工狀態。

► Shortens Marination Time and Improves Efficiency

In a vacuum environment, the meat comes into closer contact with the marinade, significantly reducing marination time and increasing production efficiency.

► Improves Meat Texture and Water Retention

The tumbling and impact inside the drum allow the meat to absorb the marinade more evenly, enhancing water retention, elasticity, and mouthfeel of the final product.

► Ensures Consistent Quality and Stability

The automated control system allows you to set massage time, rest time, total cycle time, and rotation speed, ensuring consistency and stability in every batch.

► Simulates Manual Massaging Actions

Under vacuum conditions, the meat is flipped and tumbled inside the drum, simulating kneading, rubbing, pounding, striking, and tossing actions—resulting in better flavor absorption and a more tender texture.

Machine Features and Operational Advantages

All-Stainless Steel Construction, Designed to meet food hygiene standards, easy to clean and maintain.

Stepless Speed Control, Rotation speed can be adjusted according to different product requirements, providing flexibility for various processing needs.

Multi-Program Memory Control Panel, Allows storage of multiple sets of processing parameters for quick and convenient product line switching.

Forward/Reverse Rotation and Reverse Discharge, Enhances discharge efficiency and reduces manual intervention.

Emergency Stop and Pause Functions, Ensures safer operation and allows inspection of processing status during operation.