Germany KAHL Feed Conditioning

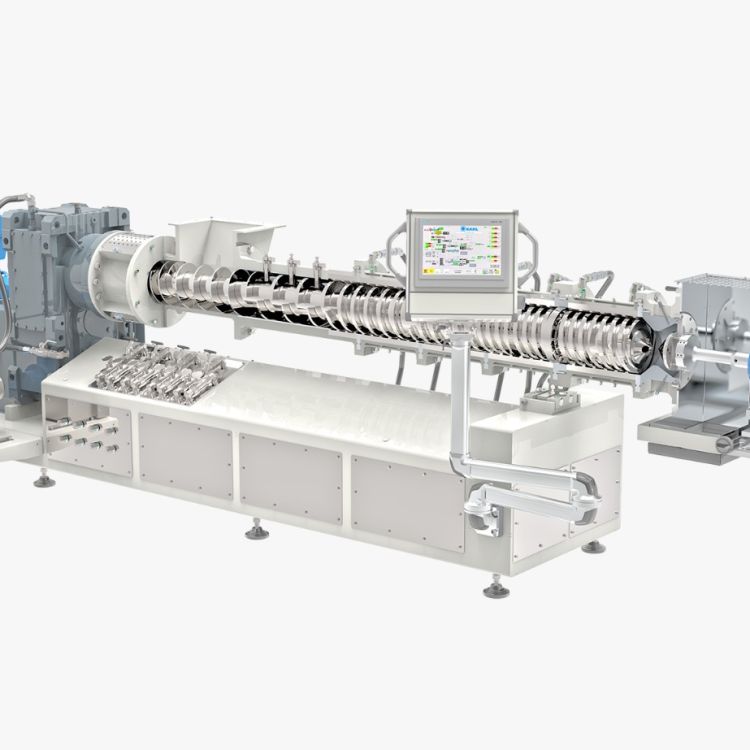

The expander, typically installed upstream of the pellet mill as a deep-pressure conditioner, employs a retention screw, mixing paddles, and precisely controlled outlet cone pressure. Feed materials pre-conditioned with water and steam undergo compression, shear, kneading, and friction within the expander chamber. This process achieves further hydrothermal conditioning before pelletizing, significantly improving pellet quality and feed performance, while increasing throughput and reducing die wear.

The KAHL Pressure Conditioning Expander combines steam-based conditioning with mechanical extrusion to perform high-pressure homogenization of feed in a short retention time. A retention screw and mixing paddles generate compression, shear, kneading, and friction on the feed material, enhancing starch gelatinization and modifying protein structures—resulting in improved water stability and mechanical strength of the pellets.

This technology also improves pellet uniformity, lowers energy consumption, increases production capacity, and reduces die wear. It is widely applicable across livestock, aquafeed, and premium pet food sectors, especially for products that require consistent quality and extended shelf life.

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

This technology also improves pellet uniformity, lowers energy consumption, increases production capacity, and reduces die wear. It is widely applicable across livestock, aquafeed, and premium pet food sectors, especially for products that require consistent quality and extended shelf life.

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

__25H1600ehv.jpg)

__25H16XXJJE.jpg)

__25H16XYl6N.jpg)