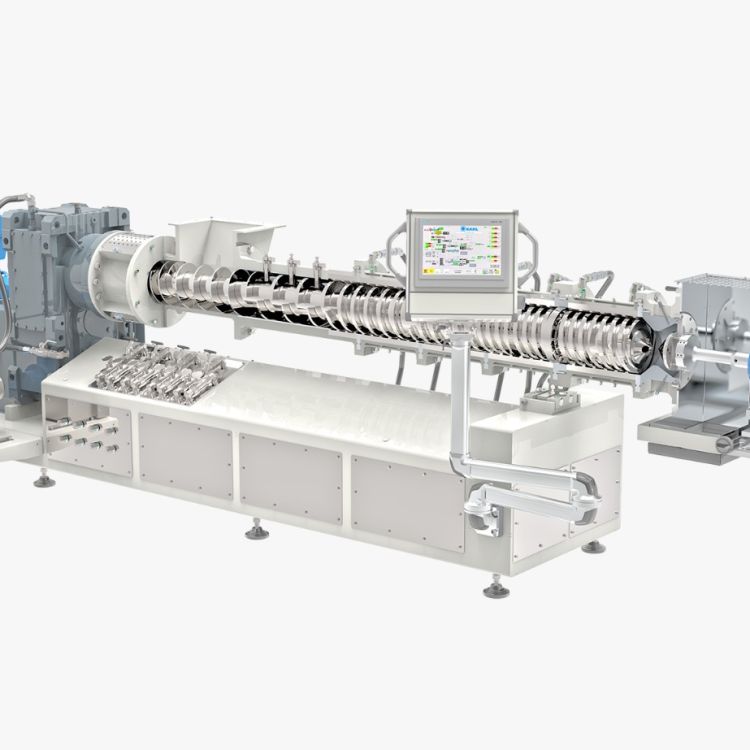

Germany KAHL Vertical Pellet Mill for Combustible Solid Waste

The KAHL flat-die pellet mill operates with a stationary die while the rollers rotate around their shafts. With a circumferential speed of only 2.3 m/s—about 40% of conventional ring-die feed pellet mills—the system offers a significantly larger feeding area. Roller pressure combined with shear and compression, supported by hydraulic cylinders and nuts, allows online adjustment of the roller gap. This makes the machine particularly suitable for pelleting wood chips, high-fiber combustible residues, and even lightweight plastics with a bulk density as low as 0.05. Through the interaction of roller pressure, shear, and temperature monitoring, plastics can be densified into pellets of the required product density before plastic deformation occurs.

The KAHL Vertical Pellet Mill for Combustible Solid Waste is designed for processing wood chips, plastic films, fibers, and other low-bulk density residues. By applying shear, compression, and frictional heat between the flat die and rollers, the system converts loose or hard-to-handle waste into dense, dust-free fuel pellets or fluff. Compared with conventional ring-die systems, KAHL flat-die technology provides a larger feeding area and greater flexibility, making it particularly effective for high-moisture and high-fiber materials. The resulting pellets exhibit uniform density and excellent combustion properties, and can be directly used as refuse-derived fuel (RDF) in cement kilns, waste-to-energy plants, or biomass boilers—offering both cost reduction and sustainable energy recovery.

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

__25H1600ehv.jpg)

__25H16XXJJE.jpg)

__25H16XYl6N.jpg)