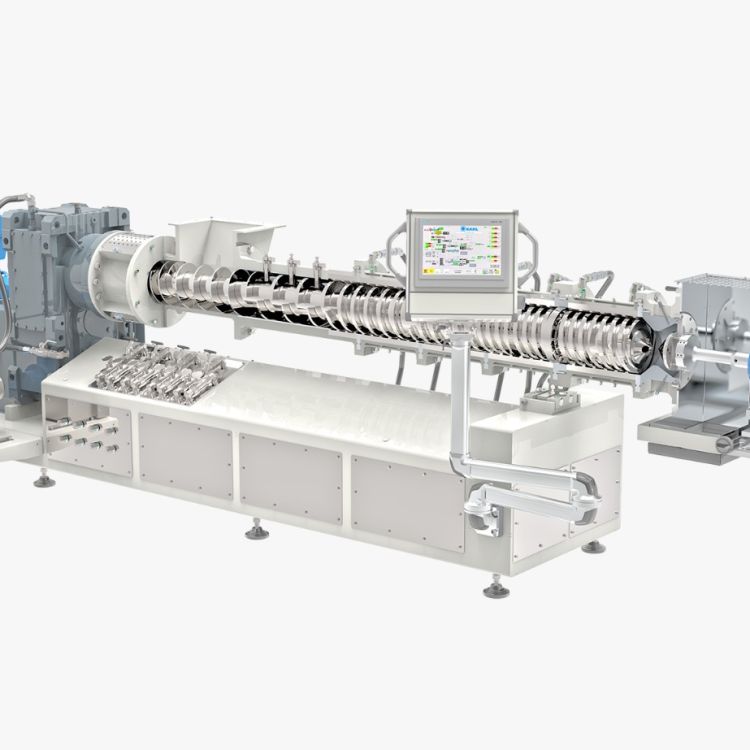

Germany KAHL Vacuum Coater

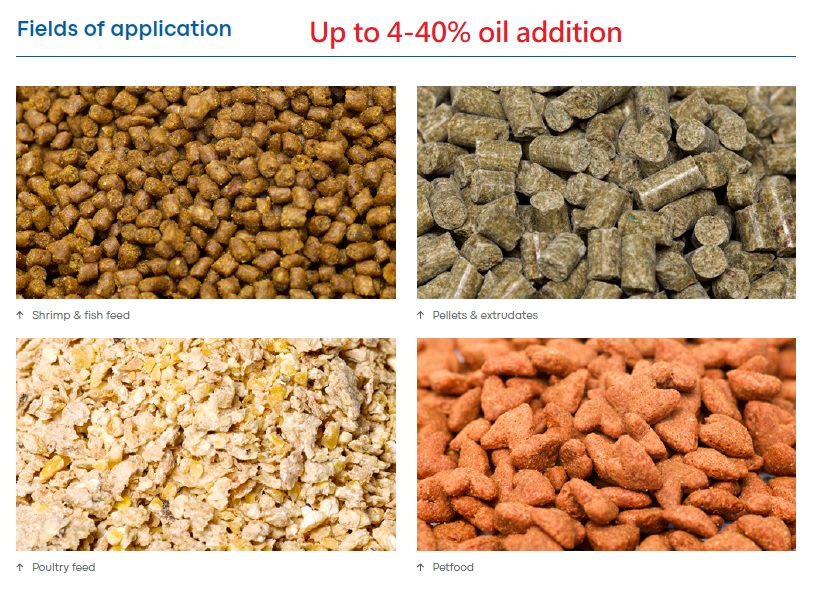

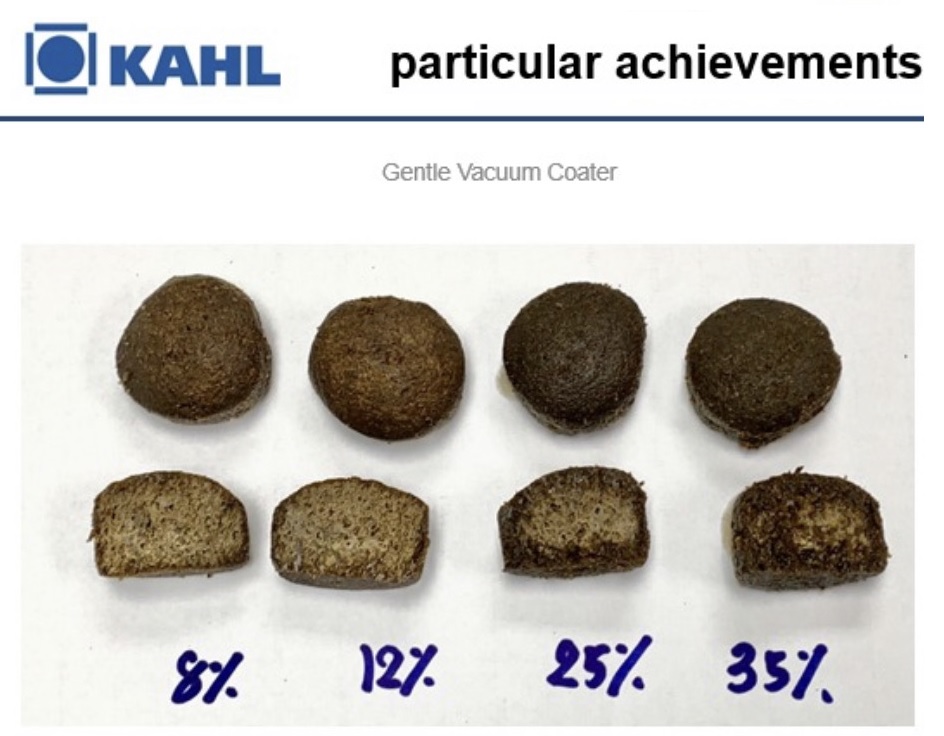

The German KAHL Vacuum Coater applies up to 4–40% oil to pellets in a gentle manner. In contrast to conventional systems, it features a vacuum pump, highly sealed scrapper valve, and an internal drum mixing design that reduces secondary breakage, making it widely applicable for oil coating of pet food and aquafeed.

- Company NameAGRIASIA DEVELOPMENT CORPORATION

The KAHL Vacuum Coater is an advanced post-processing system engineered to enhance feed quality and energy content by infusing liquids—such as oils, enzymes, or vitamins—deep into pellet pores under vacuum, achieving oil addition between 4–40% . Unlike traditional mixers with moving agitators, it employs a rotating drum with internal mixing flights, minimizing mechanical stress on pellets and significantly reducing fines and micro-cracking.

The process is controlled via precise dosing, vacuum generation, liquid spraying, vacuum release, and drum discharge stages, allowing sequential application of multiple liquids to protect sensitive additives or mask flavors. Its compact design and high flexibility for integration make it ideal for refining extruded fish feed, pet food, and compound feeds—improving product energy density, abrasion resistance, and cost efficiency.

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

The process is controlled via precise dosing, vacuum generation, liquid spraying, vacuum release, and drum discharge stages, allowing sequential application of multiple liquids to protect sensitive additives or mask flavors. Its compact design and high flexibility for integration make it ideal for refining extruded fish feed, pet food, and compound feeds—improving product energy density, abrasion resistance, and cost efficiency.

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

__25H1600ehv.jpg)

__25H16XXJJE.jpg)

__25H16XYl6N.jpg)