Germany KAHL Mono-component treatment

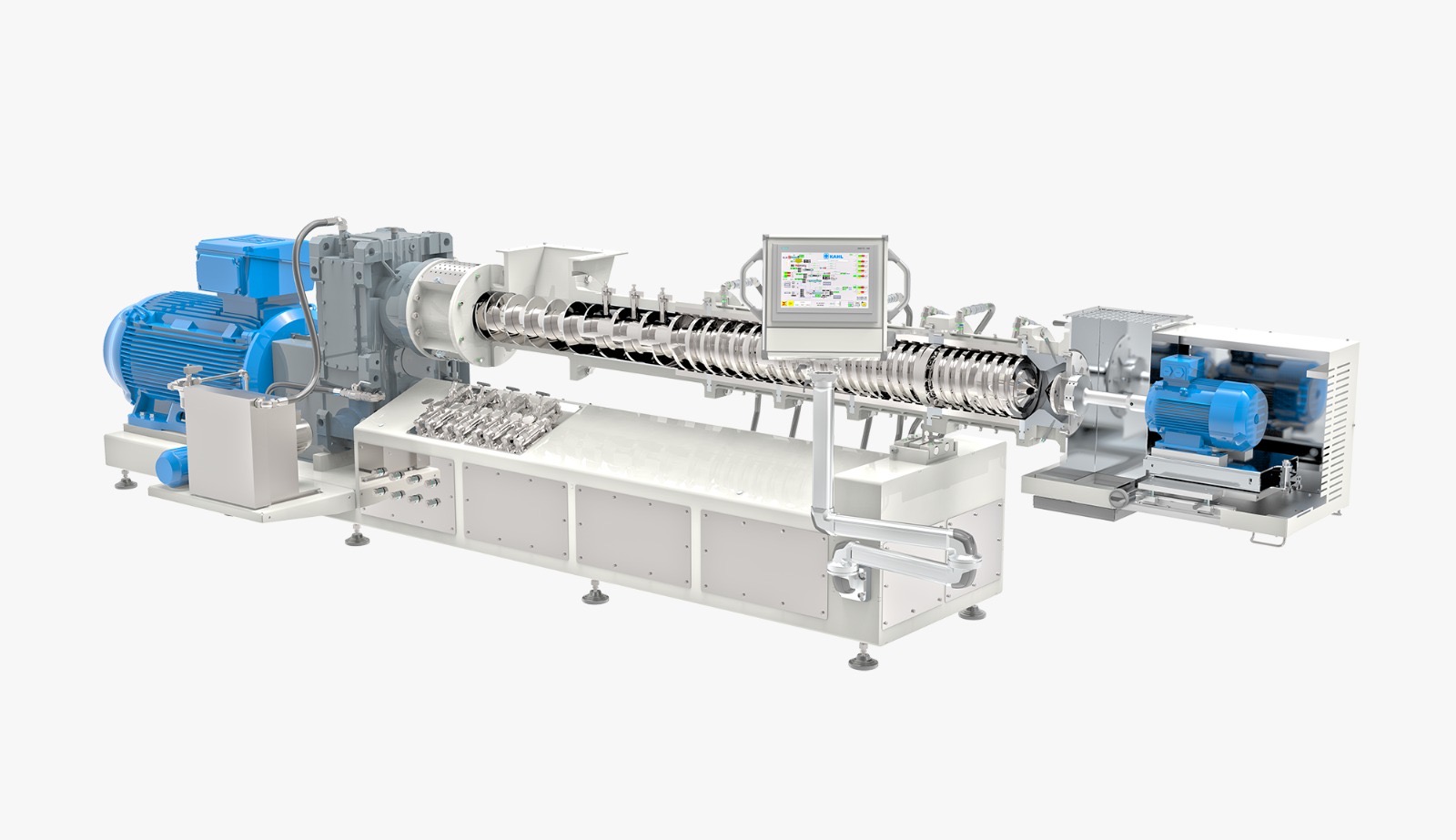

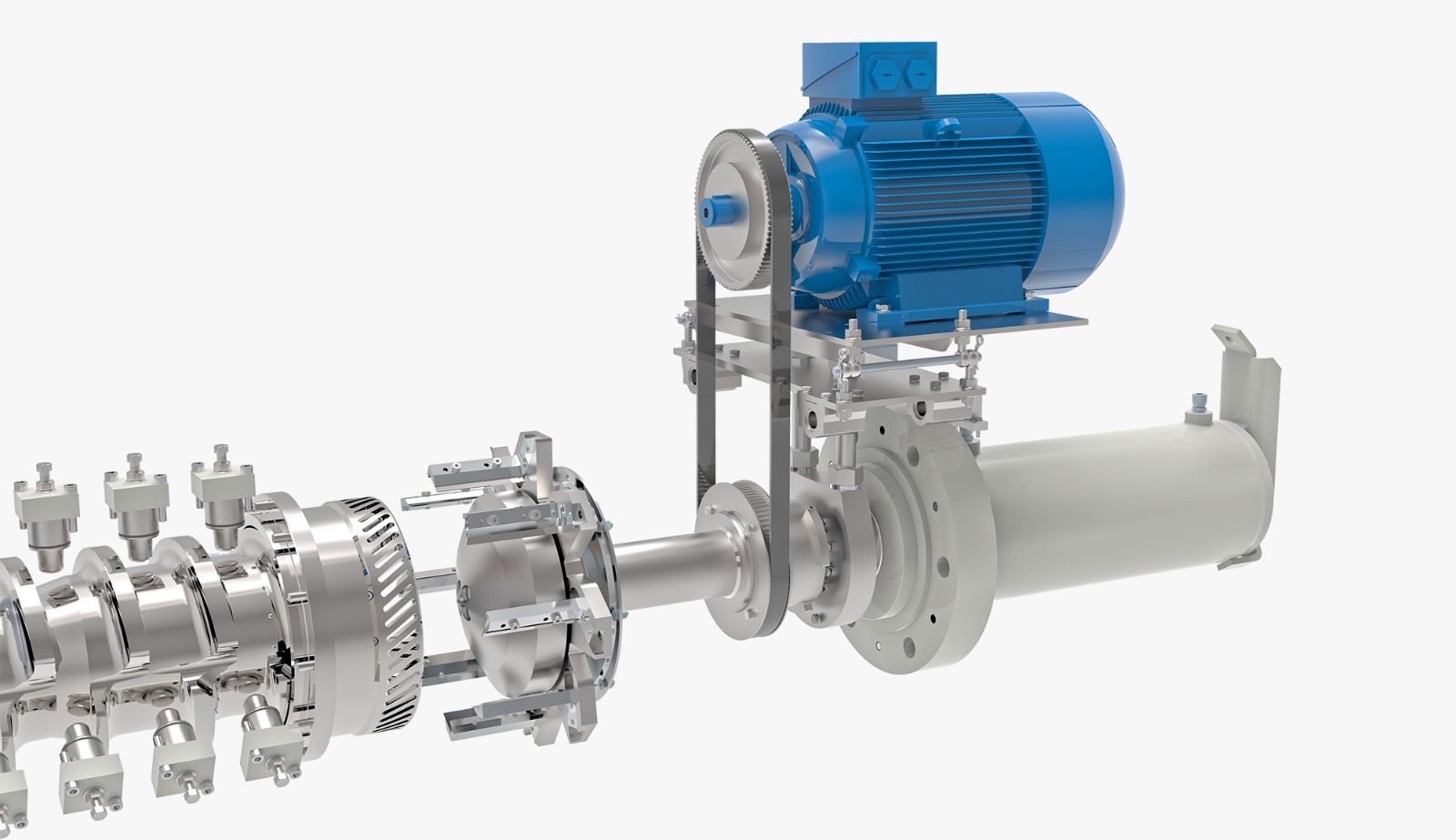

In addition to its unique hydraulic system for precise control of outlet cone pressure and energy input, KAHL’s expander can be equipped with ring dies and crown heads, making it suitable for aquafeed, pet food, and single-component raw material processing.

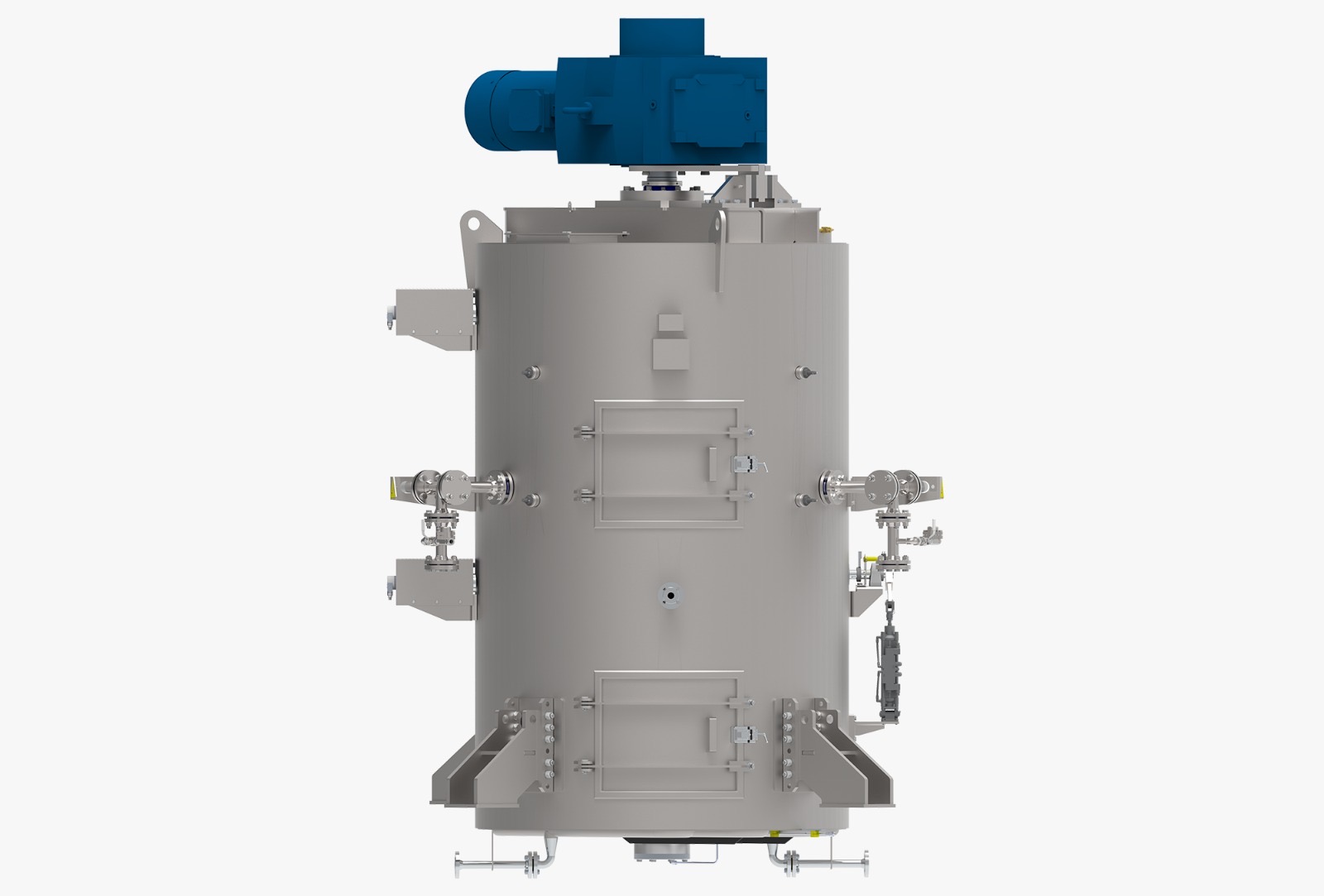

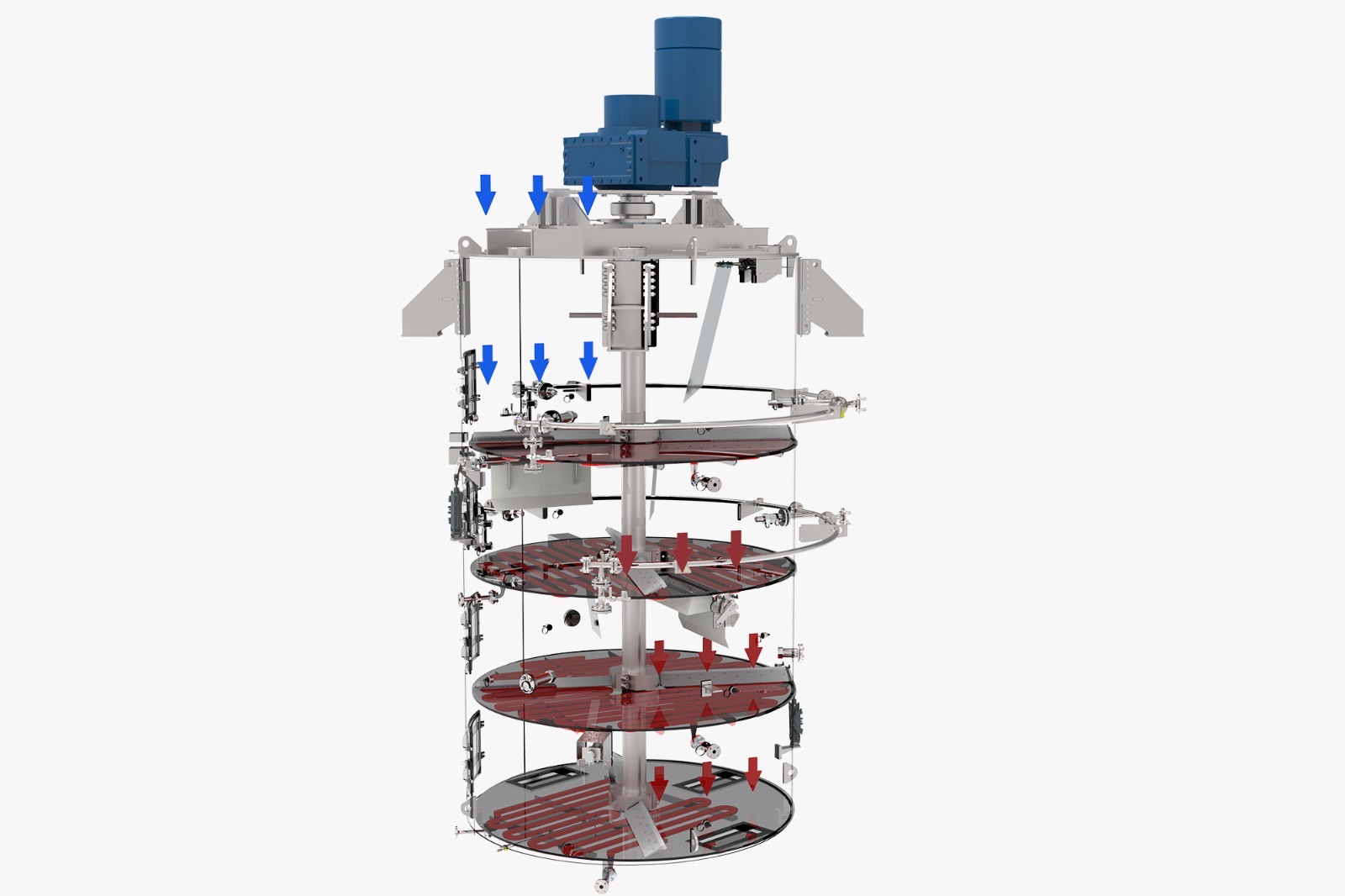

In combination with a vertical conditioner with a residence time of 8–20 minutes, the system enables the production of high-quality full-fat soybean meal with 15–25% PDI, optimally cooked maize starch for piglets, and rumen bypass protein for dairy cows.

In combination with a vertical conditioner with a residence time of 8–20 minutes, the system enables the production of high-quality full-fat soybean meal with 15–25% PDI, optimally cooked maize starch for piglets, and rumen bypass protein for dairy cows.

- Company NameAGRIASIA DEVELOPMENT CORPORATION

The KAHL Mono Component Process is a dedicated system for the treatment of single raw materials such as soybeans, rapeseed, and maize. It is typically configured with two separate processing lines (soy and rapeseed) and can achieve production capacities of up to 720 t/day.

Using crown expander technology, the system applies short-time, high-pressure hydrothermal treatment that gelatinizes starch and modifies protein structures. This creates bypass protein that is stable in the rumen but digestible in the small intestine, significantly enhancing the nutritional value of dairy rations. The process also improves pellet mill throughput, ensures uniform and durable pellets, and is widely applied in premium livestock feed, aquafeed, and pet food production—particularly where long shelf life and stable nutritional quality are required.

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

Using crown expander technology, the system applies short-time, high-pressure hydrothermal treatment that gelatinizes starch and modifies protein structures. This creates bypass protein that is stable in the rumen but digestible in the small intestine, significantly enhancing the nutritional value of dairy rations. The process also improves pellet mill throughput, ensures uniform and durable pellets, and is widely applied in premium livestock feed, aquafeed, and pet food production—particularly where long shelf life and stable nutritional quality are required.

Contact:

KAHL: https://www.akahl.com/en/

Agriasia Development Corporation: https://agriasiadc.com.tw/

__25H1600ehv.jpg)

__25H16XXJJE.jpg)

__25H16XYl6N.jpg)