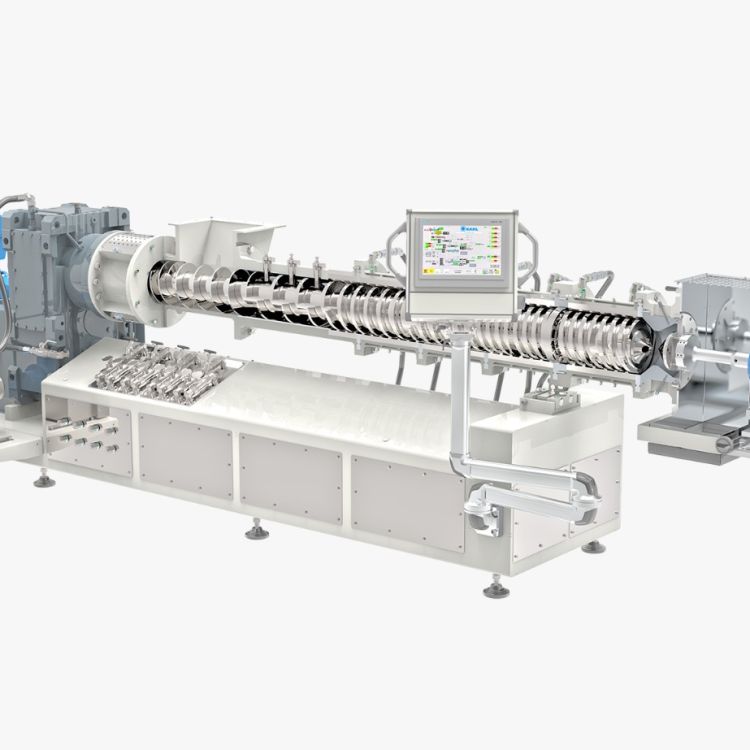

U.S. Wenger AquaFlex Twin Screw Extruders

The AquaFLEX™ twin screw extruder is Wenger’s most advanced extrusion system for aquatic feed production, designed to consistently deliver high volumes of pellets across a wide range of sizes and densities. Engineered to overcome the limitations of traditional single screw extruders, the AquaFLEX ensures excellent control of pellet density, nutrition retention, and water stability, even for small pellets under 1 mm. Its patented dual die assembly enables flexible production of floating, slow-sinking, and sinking feeds in one machine.

- Company NameAGRIASIA DEVELOPMENT CORPORATION

The AquaFLEX™ extrusion system was specifically designed to meet the complex requirements of modern aquaculture. Using twin screw technology, it excels in producing highly uniform pellets with superior water stability (up to 7 hours for shrimp feed) and precise density control. Pellet sizes range from 0.6 mm micro feeds to over 10 mm, suitable for a wide variety of species including shrimp, salmon, trout, sea bass, cod, and yellowtail tuna.

Its patented dual die system offers unmatched flexibility: both dies can be used simultaneously for high-volume sinking feed, or a single die can produce floating feed. The system also adapts to high-fiber formulations, diets with high internal fat levels, and specialized pellet shapes for portion control.

Available in two models (AFX-3000 and AFX-600), AquaFLEX delivers up to 13,000 kg/hr throughput, making it ideal for large-scale shrimp feed production while remaining versatile enough for other aquaculture and specialty feeds. Typically configured with Wenger’s High Shear Conditioner or High Intensity Preconditioner, Shutdown Oil System, and Overhead Rail System, AquaFLEX ensures complete process control and efficiency.

For pet food applications, this same extrusion technology is available under the PetFLEX™ line, demonstrating Wenger’s 90 years of innovation in extrusion systems for feed and food industries.

Contact:

Wenger: https://wenger.com/

Agriasia Development Corporation: https://agriasiadc.com.tw/

Its patented dual die system offers unmatched flexibility: both dies can be used simultaneously for high-volume sinking feed, or a single die can produce floating feed. The system also adapts to high-fiber formulations, diets with high internal fat levels, and specialized pellet shapes for portion control.

Available in two models (AFX-3000 and AFX-600), AquaFLEX delivers up to 13,000 kg/hr throughput, making it ideal for large-scale shrimp feed production while remaining versatile enough for other aquaculture and specialty feeds. Typically configured with Wenger’s High Shear Conditioner or High Intensity Preconditioner, Shutdown Oil System, and Overhead Rail System, AquaFLEX ensures complete process control and efficiency.

For pet food applications, this same extrusion technology is available under the PetFLEX™ line, demonstrating Wenger’s 90 years of innovation in extrusion systems for feed and food industries.

Contact:

Wenger: https://wenger.com/

Agriasia Development Corporation: https://agriasiadc.com.tw/

__25H1600ehv.jpg)

__25H16XXJJE.jpg)

__25H16XYl6N.jpg)