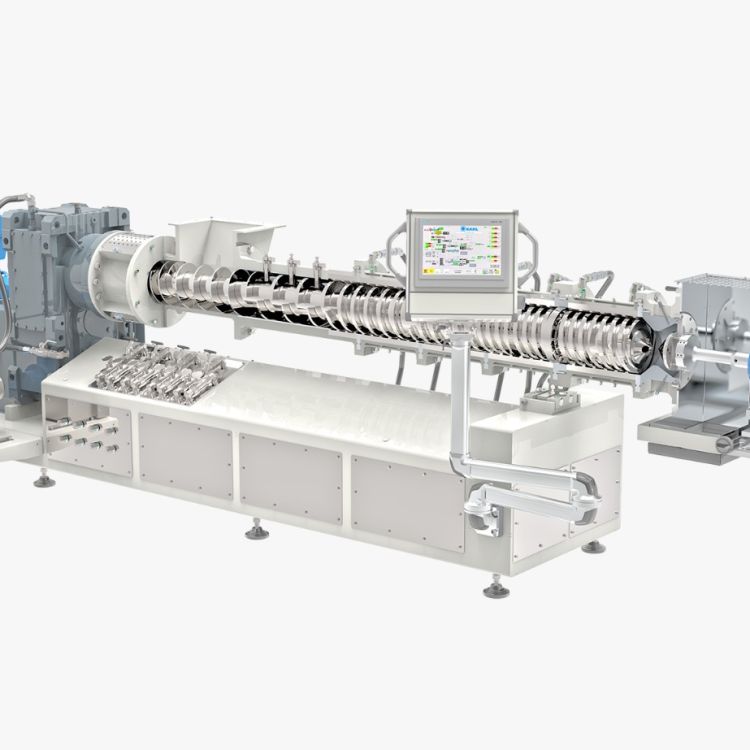

U.S. Scott Equipment High Speed Turbo Blender

The Scott high-speed turbo blender is perhaps the most flexible continuous blender on the marketplace today. It can consistently blend a wide variety of materials and can handle up to five different materials at one time. The industrial blender can mix powder with powder, powder with liquid, or several liquids to create a homogeneous product free of agglomerates or lumps.

- Company NameAGRIASIA DEVELOPMENT CORPORATION

The flexibility of the high-speed turbo blender stems from the paddles’ adjustability and the unit’s speed. By simply adjusting the paddles and the speed of the mixer shaft, the unit gives you the desired mixing results. Best suited in applications where high intensity and low retention time are needed, it is excellent for mixing small amounts of liquid with a dry powder in a coating application. Direct heat or a steam/hot oil jacket can also be added where heat and intense mixing are needed to melt and coat the powder. If cooling is required, a cooling jacket is also available.

Features:

1)Homogeneous mixing free of any agglomerates or lumps

2)Available in operating speeds up to 3000 RPMs

3)Construction materials available include carbon steel, 304 or 316L stainless steel and many different specialty materials

4)Multiple options for inlet and discharge configurations

5)Special liquid addition spray options

1. Continuous Blending Applications

The flexibility of the HST Blender makes it ideal for a wide variety of products and applications. It is best suited in an application with high intensity and low retention time.

2. HST Blender Specifc Applications

1)Coating

It is excellent for mixing small amounts of liquid with a dry powder in a coating application. Direct heat or a steam/hot oil jacket can be added where heat and intense mixing are needed to melt and coat the powder. If cooling is needed, a cooling jacket is also available.

2)Deagglomeration

This continuous mixer is also especially efficient in applications where materials need to be deagglomerated. It is often used as a finisher for cake mix and other bakery mixers. With the addition of breaker bars, the blender will serve a variety of deagglomerating or grinding applications.

3)Mixing powder, slurry, or liquid

The HST Blender is often used for mixing liquids with baghouse dust, mixing dry materials with waste sludges, and for conditioning fly ash and bottom ash.

4)Agglomeration

The unit can also be used as an agglomerator where fine agglomerated particles are formed with the addition of liquid binding agents. Adjustable paddles can be replaced with pins in some agglomeration applications.

Features:

1)Homogeneous mixing free of any agglomerates or lumps

2)Available in operating speeds up to 3000 RPMs

3)Construction materials available include carbon steel, 304 or 316L stainless steel and many different specialty materials

4)Multiple options for inlet and discharge configurations

5)Special liquid addition spray options

1. Continuous Blending Applications

The flexibility of the HST Blender makes it ideal for a wide variety of products and applications. It is best suited in an application with high intensity and low retention time.

2. HST Blender Specifc Applications

1)Coating

It is excellent for mixing small amounts of liquid with a dry powder in a coating application. Direct heat or a steam/hot oil jacket can be added where heat and intense mixing are needed to melt and coat the powder. If cooling is needed, a cooling jacket is also available.

2)Deagglomeration

This continuous mixer is also especially efficient in applications where materials need to be deagglomerated. It is often used as a finisher for cake mix and other bakery mixers. With the addition of breaker bars, the blender will serve a variety of deagglomerating or grinding applications.

3)Mixing powder, slurry, or liquid

The HST Blender is often used for mixing liquids with baghouse dust, mixing dry materials with waste sludges, and for conditioning fly ash and bottom ash.

4)Agglomeration

The unit can also be used as an agglomerator where fine agglomerated particles are formed with the addition of liquid binding agents. Adjustable paddles can be replaced with pins in some agglomeration applications.

__25H1600ehv.jpg)

__25H16XXJJE.jpg)

__25H16XYl6N.jpg)